Improve Thermal Performance and Lower Costs

The message is simple: Taking an optimized value engineered (OVE) approach to wall framing can not only significantly improve thermal performance, but also reduce your costs and deliver a more comfortable home.

Because heat passes through wood framing more easily than through common insulation products, OVE encourages builders to reduce the amount of framing in a wall as much as possible, and in turn, increase the amount of wall cavity insulation.

Consider this example: kiln-dried lumber has a thermal value of about R-1 per inch; add a ½-inch OSB sheathing and you get to R-4. On the other hand, insulation usually varies from R-13 to as much as R-24, depending on the material. And, insulation is cheaper than studs, posts, and headers (especially recently).

Problems and OVE Solutions

There are several areas within a traditional wall-framing job that can become problem areas for heat loss that proven OVE practices can solve.

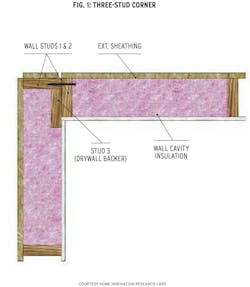

Corners. Typical practice of two studs with blocking in-between for one wall and an end-stud for the other wall creates a lot of air space in the corner that cannot be insulated. In a cold climate, this corner is so cold on the interior that warm moist air in the home will condense, potentially causing the studs to collect dust and grow mold ... especially if large piece of furniture sits in that corner, blocking air movement.

Rather than framing a conventional corner, build an open corner—often called a three-stud approach (see Fig. 1)— that permits insulation to carry much farther into that corner space, and also provides a nailing surface for the drywall. Or, you can use (and buy) even less lumber (and make even more room for insulation) by replacing one stud with either a 1x4, or “F” clips to hold the drywall in place.

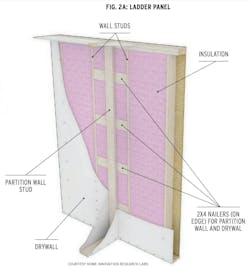

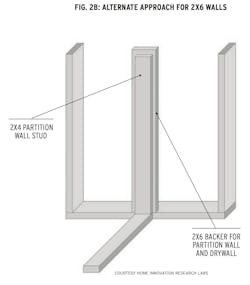

Partition tees also create large, wasteful voids in the thermal boundary.

Rather than framing a conventional partition tee, a “ladder style” tee (Fig. 2A) allows you to install insulation behind the partition. Just be sure to install the blocking on edge.

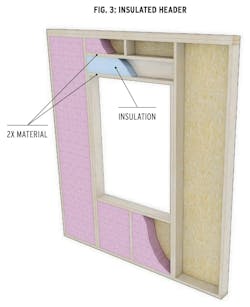

Window and door openings are framed components often built with much more framing lumber than is structurally required ... and causing significantly more thermal loss.

Specifically, headers are often over-engineered and leave no room for insulation; when I started framing homes (many years ago), we simply used double 2x12 headers over nearly every opening.

But many openings require only half that amount of structural support, and those located directly below a gable end truss are practically unnecessary because there is virtually no load on the wall.

Ask your structural engineer to reduce header sizes to only what is required. Those under gable-end trusses can often be reduced to a pair of 2x4s.

There are also a number of ways to insulate headers. Instead of a double layer of 2x material for a 2x4 thick wall, replace the spacers with ½” EPS or XPS foam panels (Fig. 3). On 2x6 walls, the headers can be pushed to the exterior of the wall, leaving a 2½” void to be filled with insulation or foam board.

With these basic OVE techniques, you’ll improve thermal performance, lower your lumber costs, and be confident your homeowners will experience better indoor comfort and overall satisfaction.

Graham Davis drives quality and performance in home building as a building performance specialist of the PERFORM Builder

Solutions team at IBACOS.

This story originally ran as part of IBACOS's and Pro Builder's joint 'Quality Matters' series.