Simple and fun introduction to lean concepts: Thinking outside the dome

Using Lean concepts can be very powerful; the trick is using them correctly. In an earlier blog I discussed ‘Lean and Six Sigma in Construction’ (available at the following link) where I described the different types of waste and key elements to focus on when using lean.

https://www.probuilder.com/blog/lean-six-sigma-construction

However, when introducing the concept of lean there is the danger of over complicating and even missing the point. A simple workshop session which is meant to be fun, engaging and to help your team think outside the box is ‘The Concrete Dome’.

Start with the problem, which is that we are being asked to design and build a concrete dome 142 feet in diameter. How can we reduce the weight of this concrete dome?

Break into small teams and by encouraging brainstorming and using tools such as fishbone diagrams allow the teams to come up with their own ideas. You can handle the session in a number of ways, you can set a time have each team list out their ideas and have the teams select what they consider to be the top 5 ideas. You can then provide a one or two of the solutions listed below discuss them and then have the teams as one group discuss any new ideas that have now developed.

Finally, you can share the original solutions to this particular concrete dome project.

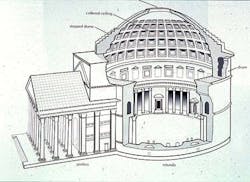

The project was the Pantheon in Rome built in 126 AD by Emperor Hadrian, it is still the world’s largest unreinforced concrete dome.

The dome weighs 4,535 metric tons and is 142 feet in diameter, as is the distance from the floor to the apex of the dome. The oculus or opening at the top of the dome is 30 feet in diameter.

The solutions the Romans came up with included:

- Using a stepped concrete dome which reduced the thickness of the dome wall as it reaches the apex.

- Used coffers to further reduce thickness of dome wall at all levels, these were created by using molds supported on scaffolding.

- Designing in an oculus or opening at the top of the dome. This eliminated a huge amount of concrete at the most difficult engineering point of the dome. It also provided natural air flow and light.

- Small amphoras (or jars) were mixed into the concrete to help reduce the weight of the concrete by creating voids.

These solutions were brilliant and yet deceptively simple. You can see the stepped element of the dome, coffers in the ceiling and oculus in the diagram.

The point is that the same solutions could work today, however, it’s not about ‘getting the right answer’ it’s about at this point of introduction thinking out of the box, about providing the product to the specifications required, meeting customer expectations yet doing so using less material, labor and time for example. It provides a great opportunity to use teams, facilitation, brainstorming and the use of other quality tools.

Some background information.

Roman concrete ingredients are similar to that used today, but they used them in a vastly different manner. A semi-fluid mixture of lime, pozzolan, and small stones or brickbats was poured in then a layer of larger stones, from 3 to 6 inches across, was laid by hand. Then a second layer of fluid cement was poured in, and so on.

Pozzolan is a finely crushed volcanic ash which acts in a similar way to Portland cement does today by chemically bonding lime to clay through the application of heat.

Roman concrete has a modern-day zero-slump and a 213 psi.

If you like this blog check this earlier blog also on ancient construction.

https://www.probuilder.com/blog/great-pyramid-and-pantheon-ancient-construction-quality

It also happens to focus on an element with the pantheon as well as the great pyramid.